Manufacture of Complex Machined Components at Low to Medium Volumes

LOW TO MEDIUM VOLUMES

LOW TO MEDIUM VOLUMES

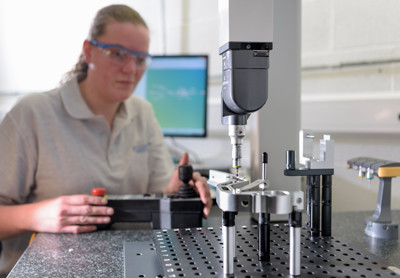

In addition to manufacturing many products in millions of units, Fylde CNC also produces complex components in lower volumes. We are able to measure complex parts on the machine by using in-cycle Renishaw probing technology, and using our Faro Arm allows us to easily verify product quality by performing 3D inspections, CAD comparison and dimensional analysis.

REVERSE ENGINEERING

With the use of our Faro Arm, we are able to generate missing CAD files, allowing us to quickly digitise parts which can then be reproduced.

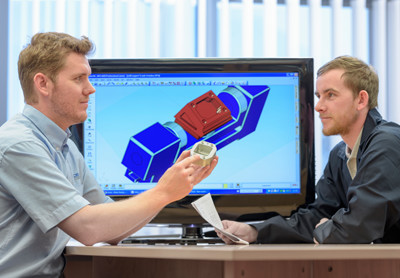

RAPID PROTOTYPING

RAPID PROTOTYPING

Our rapid prototyping capability allows us to turn great ideas into successful products faster than ever before. With the ability to start producing one-offs,

the risk of faults and usability issues can be identified earlier to avoid problems that might occur during the manufacturing process. Components that previously may have required three or four separate processes can now be manufactured by Fylde CNC in one process, resulting in significant cost savings.

SECTORS

SECTORS

Fylde CNC works with many sectors including:

- Aerospace

- Defence

- Motorsport & Automotive

- Medical

- Electronic & Telecoms

- Food & Drink

- Oil & Gas

- Hydraulics & Pneumatics

Examples of our products used in the above sectors include:

- Various components for the automotive and motorsport sectors

- General steel components

- Safety critical couplings

- Hydraulic and pneumatic control valves

- Subsea valves

- High pressure hose assemblies

- Cockpit control panels

- Aluminium enclosure units for military and commercial

- Seating components

- Landing gear systems

- Bulkhead components

- Instrument and display components

- Medical prosthetics and assistive technology

- Medical instruments for minimally invasive surgery (MIS)

- Electrical connectors

QUALITY

QUALITY

Fylde CNC specialises in supplying high quality, complex CNC machined components, from small to large parts, from prototype stage to small and medium batches in one single set-up. We also offer a rapid response service for those parts required on a fast-track basis, and we are proud of our record of on-time delivery with zero defects.

- Products are developed using advanced product quality planning (APQP) in order to ensure new projects run smoothly.

- Production part approval process (PPAP) guarantees confidence in new products and provides full documentation.

- We operate ISO 9001 quality management systems and are working towards AS 9001 & TS 16949 approval.

- We carry out a feasibility review at the quotation stage of both the component and the planned manufacturing process.

- Precise quality inspections are carried out in our state-of-the-art metrology lab.

- Use of the PSL Datatrack production management system ensures a streamlined process and full traceability from quote to delivery.

TECHNICAL CAPABILITY

TECHNICAL CAPABILITY

The Fylde CNC factory features state-of-the-art advanced multi-tasking machining, delivering maximum versatility, high precision and throughput for medium to large complex parts. We combine the capabilities of high-powered turning centres and full-function machining centres to produce parts in single set-ups. This machine configuration works to minimise fixtures, tools, handling and non-cut time.

Additionally, the machines bring dramatic reductions in lead-time and improve part accuracy through the elimination of multiple set-ups. With full 5-axis machining capability, the machines easily process fully prismatic parts from solid blocks or castings (chucked or bar fed), round parts, or highly contoured parts.

We can also manufacture using a variety of materials ranging from stainless steels to more exotic materials, including:

- Aluminium

- Aluminium Bronze

- Brass

- Copper

- Stainless Steel

- Standard Duplex

- Super Duplex Steel

- Titanium

- Plastics